|

PORTABLE PIPE HANGERS (CANADA) |

|

PORTABLE PIPE HANGERS (CANADA) |

|

click image to enlarge

|

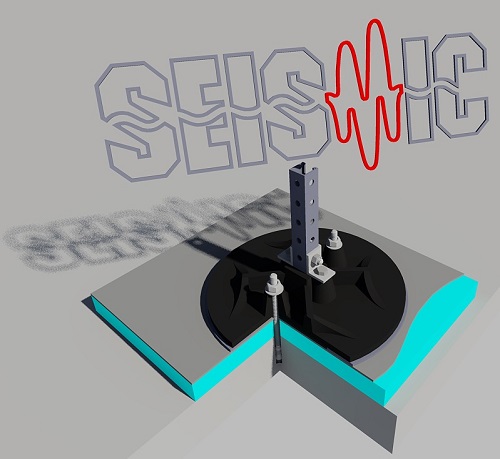

PHP Seismic Applications: Pipe & Duct Supports, Platforms & Crossovers, or Custom PHP Products- for built-up, single-ply and sloped, standing seam metal roofs.

The system shall be designed to support all weight and equipment as required.

The system shall consist of the following:

| Bases | Anchors | Frame | Platform | Clamping Hardware |

| High Density Polyethylene Plastics and other additives for UV Protection. |

5/8"x11NC HDG Wedge Anchors or Threaded Rods. |

12 gauge, 1 5/8" HDG 3-Hole or Solid strut, or approved equal. |

13 gauge Shur Grip safety grating planks, or approved equal. |

HDG or Electro-Plated Bolts, Nuts and Washers |